Unleashing the Power of Computer Vision for Seamless Inventory Management – A Step-by-Step Guide

Table of Contents

- Introduction

- Why Computer Vision?

- Building the Model

- Integration and Deployment

- Challenges and Future Trends

- Conclusion

- Frequently Asked Questions

Introduction

The inefficiencies in inventory management are an ongoing battle for retailers. Overstocking uses up funds, out-of-stocks annoy customers, and manual counting is labor-intensive and prone to mistakes. Bring on computer vision! Retailers' approach to inventory management is being revolutionized by this intriguing technology, which offers intelligent eyes. This is a thorough tutorial on creating and implementing a computer vision model for better inventory control.

Why Computer Vision?

Tracks inventory automatically : Cameras track products on shelves all the time, recording information in real time about their presence, quantity, and even damage.

Boosts accuracy : Removes human error, producing better data and more intelligent choices.

Increases productivity : Releases employees from tiresome duties so they can concentrate on providing customer care or other value-added activities.

Offers more profound understanding : More sophisticated models are able to forecast demand, examine trends, and allocate space optimally.

Building the Model

1.Data Collection

Capture photographs in a variety of lighting settings, shelf configurations, product placements, and package options. Include close-ups, wide vistas, and viewpoints that depict real-world store settings.

To improve the model's ability to generalize, aim for a broad and diverse dataset. Begin with a few thousand photographs and gradually expand the number of images dependent on your resources and desired precision.

For gathering data, there are several websites that one can visit, such as Kaggle,UC Irvine Machine Learning Repository,Dataset Search etc.

2.Data Annotation

Annotate each image with bounding boxes around each product and labels indicating product type and number. Either a manual process or specialist annotation tools like Labellerr can be used for this.

3.Model Selection

Object identification: If your primary purpose is to count and locate products, try using popular object identification techniques such as YOLO, SSD, or Faster R-CNN.

Semantic Segmentation: Investigate semantic segmentation models such as U-Net or DeepLabv3 if you need to distinguish between various product classes or locate vacant spots on shelves.

Pose estimation: This is helpful for figuring out where to put and how to orient products, especially if they have a strange shape. Investigate models such as OpenPose and AlphaPose.

4.Model Training

Preprocessing: To improve model training, scale and normalize photos, change the colors, and improve features.

Testing, Validation, and Training Split: Assign labels to distinct sets of data for testing (determining ultimate correctness), validation (adjusting hyperparameters), and training (learning the model).

Hyperparameter tuning: To maximize model performance for a particular dataset and task, modify parameters like as learning rate, optimizer, and network design.

Early Termination: To avoid overfitting, track training progress and halt training when errors on the validation set cease to decrease.

5.Model Optimization

Transfer Learning: Apply trained models (e.g., ResNet, VGG16) and adjust them for your particular data. When compared to training from scratch, this may be quicker and use less data.

Model Pruning: To minimize model size and computing expense without appreciably affecting accuracy, eliminate unnecessary connections or neurons from the network.

Quantization: In order to reduce memory footprint and facilitate deployment on low-power devices, convert model weights to lower precision formats such as int8 or int16.

6.Evaluation and refinement:

Measure Metrics: Utilize pertinent metrics such as accuracy, precision, recall, and F1-score to assess your model's performance on the test set.

Analyze errors: Determine the model's prevalent errors and the reasons (occlusion, illumination, etc.) for them. To solve these problems, think about gathering more data or changing the training parameters.

Continuous Improvement: Monitor the model's performance over time and make retraining or other changes as appropriate.

Integration and Deployment

Connect the model to the inventory management system you currently have in place. This could include developing custom applications or integrating APIs.

Before implementing the system widely, conduct a pilot test in a limited area of your store. Examine the outcomes and make any system improvements.

Challenges and Future Trends

1.Model Accuracy: It's still difficult to get reliable performance under various lighting scenarios, product placements, and packaging variances.

2.Cost and Technology: Computer vision system maintenance and infrastructure setup can be costly.

3.Data Privacy: The usage of consumer data in retail establishments is surrounded by ethical issues.

In spite of these obstacles, computer vision in retail has a promising future:

1.Advanced Algorithms: AI algorithms are always improving, offering even more precision and flexibility.

2.Edge Computing: On-device processing will lower expenses while enhancing performance.

3.Personalisation: Based on consumer demographics, unique purchasing patterns, and store architecture, computer vision can be utilised to personalise inventory management.

Conclusion

Careful data collection, deliberate model selection, and intensive training and optimisation are necessary to create a solid computer vision model for inventory management. Retailers may realise the revolutionary potential of this technology by employing sophisticated algorithms and hardware to handle typical obstacles like data privacy and accuracy in different surroundings. Computer vision will provide seamless consumer experiences and personalised inventory management in the future.

Frequently Asked Questions

Q1.How is computer vision used in inventory management?

Think about cameras taking stock in place of people! Smart cameras with computer vision replace manual counting by using their ability to recognise, locate, and measure things on shelves or in warehouses. Algorithms interpret pictures, giving real-time stock information, avoiding stockouts, and maximising restocking. It lowers errors, frees up staff, and provides insightful information for more intelligent inventory management.

Q2.Which computer application is used for inventory management?

A variety of tools use computer vision for inventory management, yet there isn't one all-inclusive programme. Retailers have three options: buy systems specifically designed for them, have vision APIs integrated into their current software, or look into specialised platforms that include AI-powered data analytics, shelf monitoring, and stock counting. The secret is to find a solution that works well with the gear and workflow you already have.

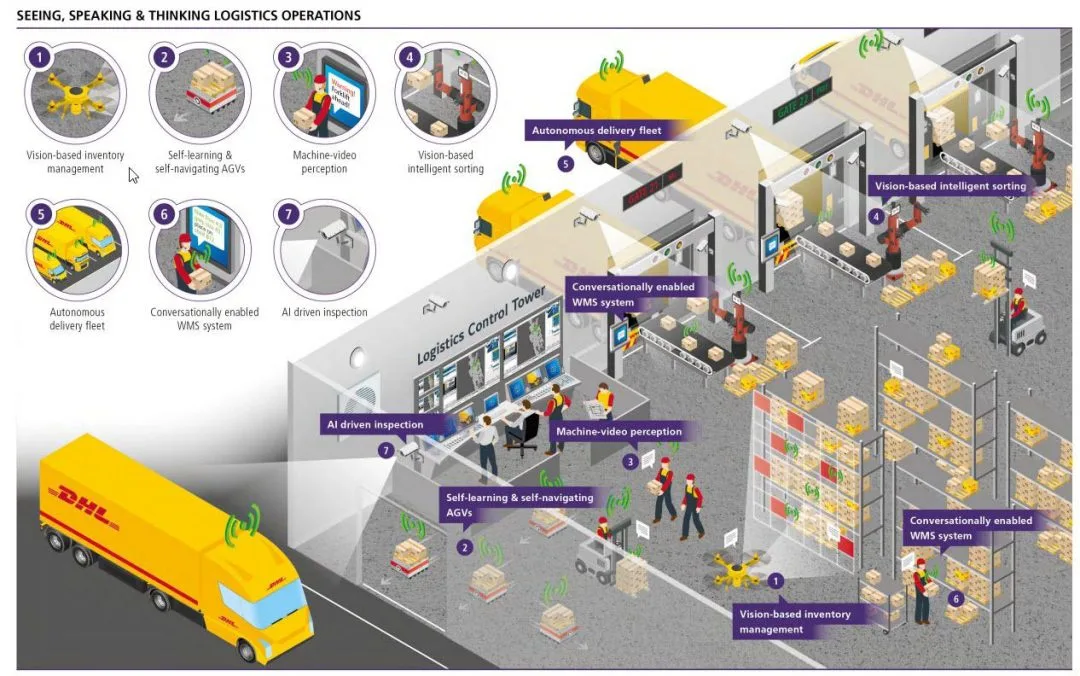

Q3.How is computer vision used in logistics?

Computer vision improves supply chain operations even beyond retail shelves. Cameras monitor loading and unloading procedures, automate package tracking throughout shipment, and keep an eye on shipments in warehouses. Artificial intelligence systems can detect faulty products, guarantee accurate labelling, and anticipate possible setbacks for proactive troubleshooting. This results in logistical operations that are quicker, more effective, and more affordable.

Simplify Your Data Annotation Workflow With Proven Strategies

.png)