How Spare-It Uses Labellerr to Revolutionize Waste Segmentation - A Case Study

Table of Contents

- Introduction

- Our Customer

- Data Volume and Accuracy Challenge

- How Labellerr Stepped In

- Results and Impact

- Conclusion

- Frequently Asked Questions

Introduction

Sustainability is a big deal worldwide, and companies like Spare-It are leading the way by using technologies like AI/ML to make a difference.

Spare-It had a tricky task on its hands of sorting through more than 10,000 pictures of waste to help the environment.

They needed a high accuracy of 99% for over 100 different types of waste, and they had just 24 hours to do it.

That's where Labellerr came into the picture, making sure Spare-It could pull off this ambitious mission.

Our Customer

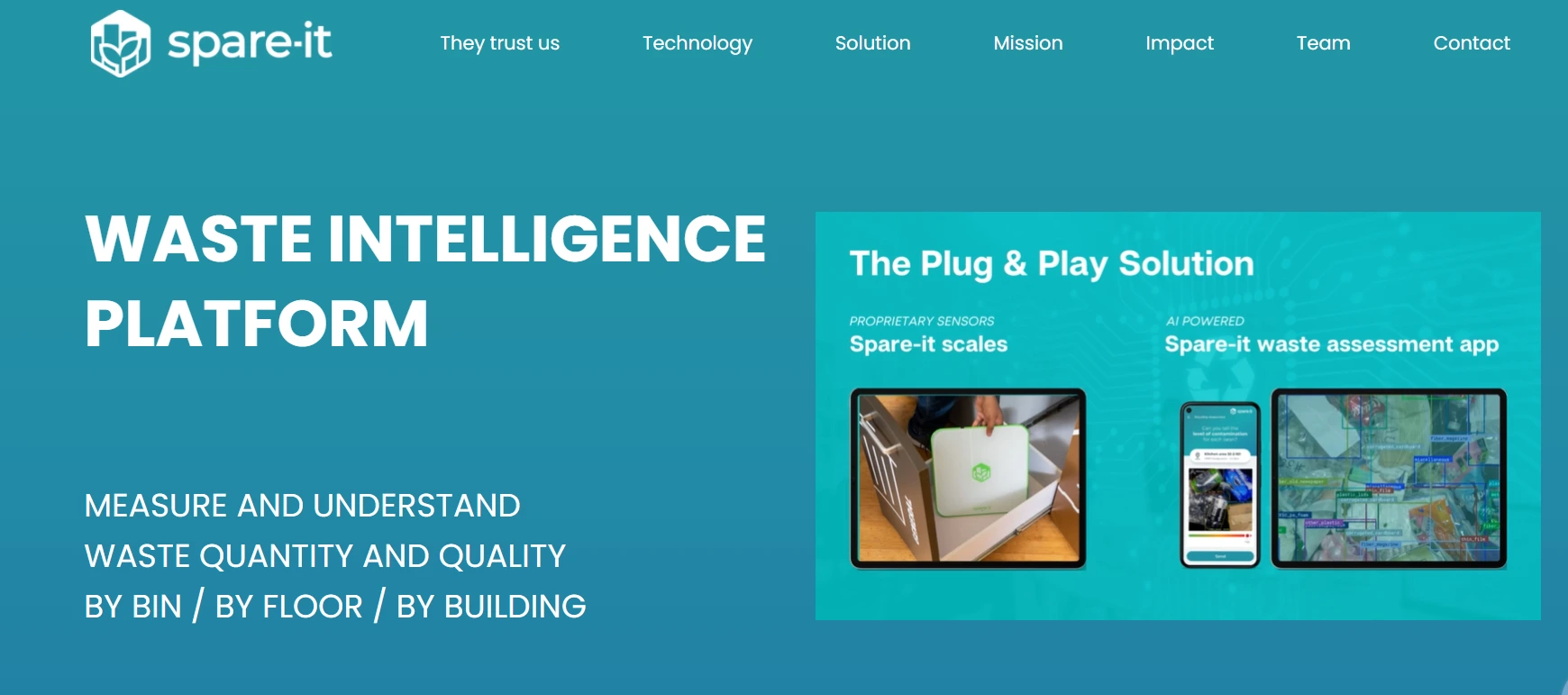

Our customer (Spare-it) stands out as the pioneering platform that provides access to real-time waste intelligence within your buildings.

Utilizing this data, they actively involve users, promote circular practices, and work towards minimizing various types of waste.

They use this information to get people involved, make things more circular (which means using stuff again instead of throwing it away), and cut down on all sorts of waste.

Data Volume and Accuracy Challenge

Spare-It faced a significant challenge that required tackling two key aspects: the large volume of data and the need for high accuracy.

They had to handle a massive collection of over 10,000 waste images, and each of these images had to be carefully sorted into more than 100 specific categories.

Achieving an accuracy rate of 99% added an extra layer of complexity, making the project not only time-sensitive but also intricate, as precision was crucial in meeting their goals.

How Labellerr Stepped In

1. Easy Data Import and Connectivity

Labellerr's capability to effortlessly import data from the cloud proved indispensable for Spare-It.

This feature ensured a seamless and continuous flow of thousands of images at regular intervals, addressing the volume challenge effectively.

2. Intuitive UI for Faster Segmentation

Labellerr's user-friendly interface played a pivotal role in accelerating the labeling process.

The easy-to-use segmentation tools not only made the project faster but also facilitated smoother quality control, ensuring the desired accuracy.

3. Efficient Workflow Management

With Labellerr, Spare-It efficiently managed the complexity of dealing with 100+ waste classes.

Labellerr's workflow management capabilities enabled the onboarding of multiple expert annotators, ensuring a robust verification process and contributing to achieving the 99% accuracy goal.

4. Complete Automation for Minimal Intervention

Labellerr's complete automation of the data pipeline reduced Spare-It's weekly intervention time from five hours to a mere 10 minutes.

This allowed Spare-It to focus on its sustainability goals, with minimal manual effort.

5. Seamless Collaboration for Guideline Clarity

Effective collaboration between Spare-It's team and Labellerr ensured that annotation guidelines were updated quickly and understood by all.

Labellerr became the central hub for communication, ensuring consistency in the annotation process.

Results and Impact

The collaborative effort between Spare-It and Labellerr turned what could have been months of effort into a matter of days.

The speed, accuracy, and efficiency of Labellerr's annotation capabilities significantly contributed to Spare-It's success in achieving the 99% accuracy target within the stringent 24-hour timeframe.

Conclusion

Labellerr's pivotal role in Spare-It's sustainability initiative highlights the transformative potential of advanced annotation tools in addressing complex challenges.

The partnership not only met but exceeded expectations, showcasing the power of technology in driving forward ambitious projects that contribute to a more sustainable future.

Labellerr stands as a commendable ally in the pursuit of impactful solutions for global challenges.

Frequently Asked Questions

1. How do we solve the waste object segmentation problem?

To solve the waste object segmentation problem, we employ computer programs. These programs are like digital detectives that analyze pictures of waste and figure out the boundaries between different types of waste.

It's akin to training a computer to recognize and separate various kinds of waste in images, helping us organize and handle waste more effectively.

Essentially, it's about making technology smart enough to understand and categorize different items in waste pictures.

2. Can a fully automated waste management system implement waste segregation?

Yes, a fully automated waste management system can implement waste segregation.

Automation in waste management systems often involves advanced technologies such as sensors, robotics, and artificial intelligence.

These technologies can be programmed to identify and sort different types of waste materials based on predefined criteria.

Automated sorting systems can efficiently segregate waste into categories like recyclables, organic waste, and non-recyclables.

By incorporating advanced automation, waste management systems can enhance the effectiveness of waste segregation processes, leading to more sustainable and environmentally friendly practices.

3. How machine learning is used in waste management?

Machine learning is employed in waste management to enhance efficiency and decision-making processes.

Through the analysis of vast datasets, machine learning algorithms can identify patterns and trends, helping optimize waste collection routes, predict waste generation patterns, and improve recycling processes.

Image recognition technology powered by machine learning aids in automated sorting of recyclables from mixed waste.

This not only streamlines operations but also contributes to resource conservation and environmental sustainability by promoting more effective waste reduction and recycling strategies.

Simplify Your Data Annotation Workflow With Proven Strategies

.png)