Enhancing Automated Vehicle Inspection through Computer Vision

Table of Contents

- Introduction

- Computer Vision in Vehicle Inspection

- Telematics in Vehicle Inspection

- Brief Steps Involved in Vehicle Inspection System

- Computer Vision and Telematics in Car Inspections

- What Are The Advantages Of Using Computer Vision And Telematics Together?

- Conclusion

Introduction

In the realm of car damage inspection, the integration of telematics and computer vision has emerged as an increasingly pivotal facet. These technologies not only facilitate continuous monitoring of vehicle health but also possess the capability to predict potential issues.

Moreover, they furnish drivers with invaluable insights into anticipated repair costs and even aid in determining the appropriate retirement time for a vehicle, if necessary. Undoubtedly, these innovations are indispensable for ensuring precise and comprehensive car inspections.

This blog aims to delve into the foundational aspects of computer vision and telematics before exploring their applications in conducting thorough vehicle assessments. Delving deeper into the intricacies of car inspections, we will specifically highlight the instrumental roles these technologies play and elucidate their advantages.

The ability to discern and address vehicle defects holds paramount importance across various domains, including border control, insurance, and security systems. As computing capabilities and graphical processing units continue to advance, the commercial viability of automated vehicle inspection solutions is rapidly gaining ground.

Get prediction of LabelGPT on automotive detection click here.

Computer Vision in Vehicle Inspection

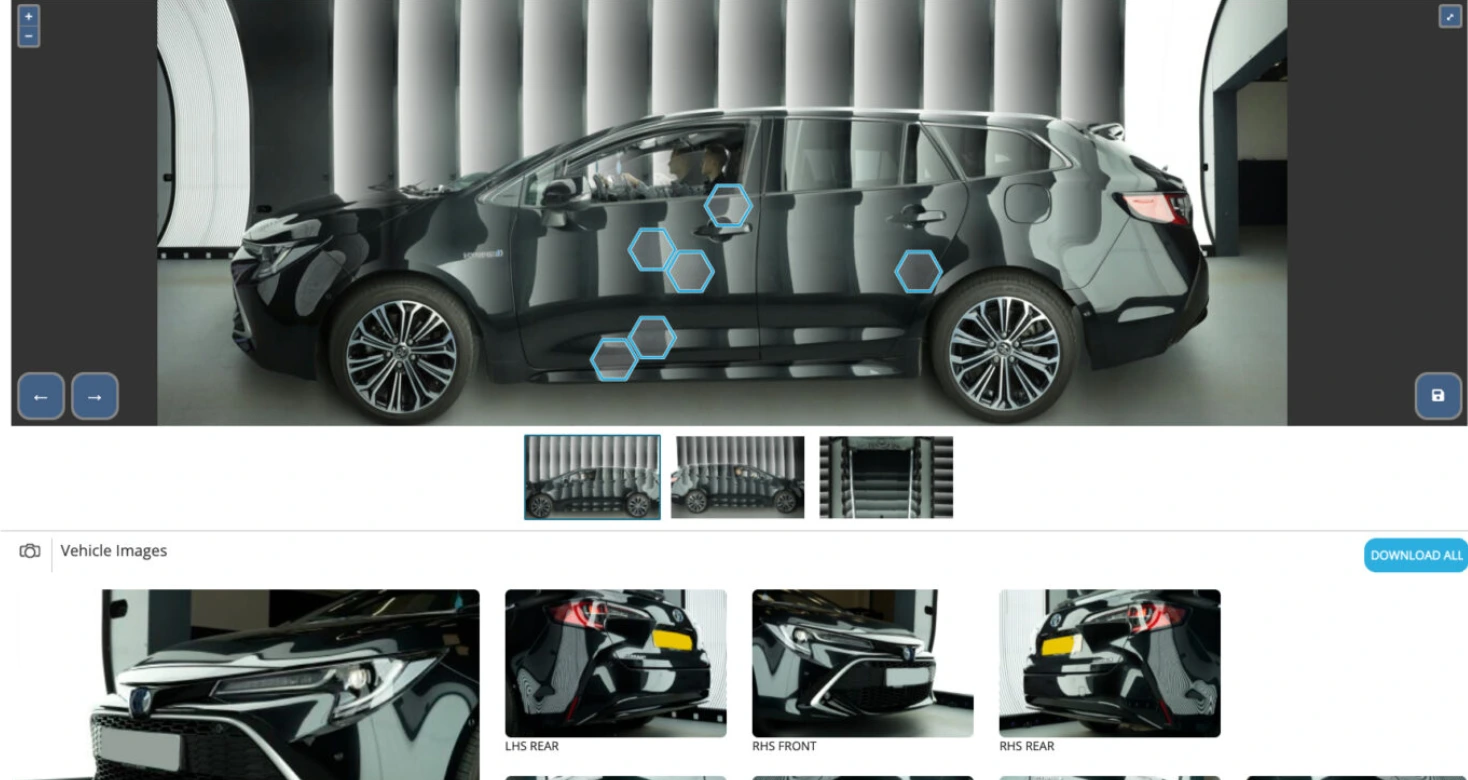

Computer vision, combined with application-specific telematics, presents a spectrum of advantages within car inspection, ranging from vehicle tracking to risk evaluation. Additionally, it aids in mitigating litigation costs and enhancing driver safety while offering car owners the potential to reduce insurance rates.

In the automotive sector, computer vision serves to elevate product quality significantly. Previously reliant on manual inspection—a subjective, time-intensive, and challenging process, computer vision now automates component inspections. By deploying multiple cameras along production lines, real-time defect detection becomes feasible.

For instance, it monitors wheel coating intensity and identifies issues in the painting process. Detailed high-resolution scans unveil intricate details like rust, screws, and other damages to the undercarriage and various vehicle components. Following image analysis, a confidence score bolsters precise vehicle identification. This technology's scope extends to car damage detection, benefiting insurance, rental, and used car industries alike.

Telematics in Vehicle Inspection

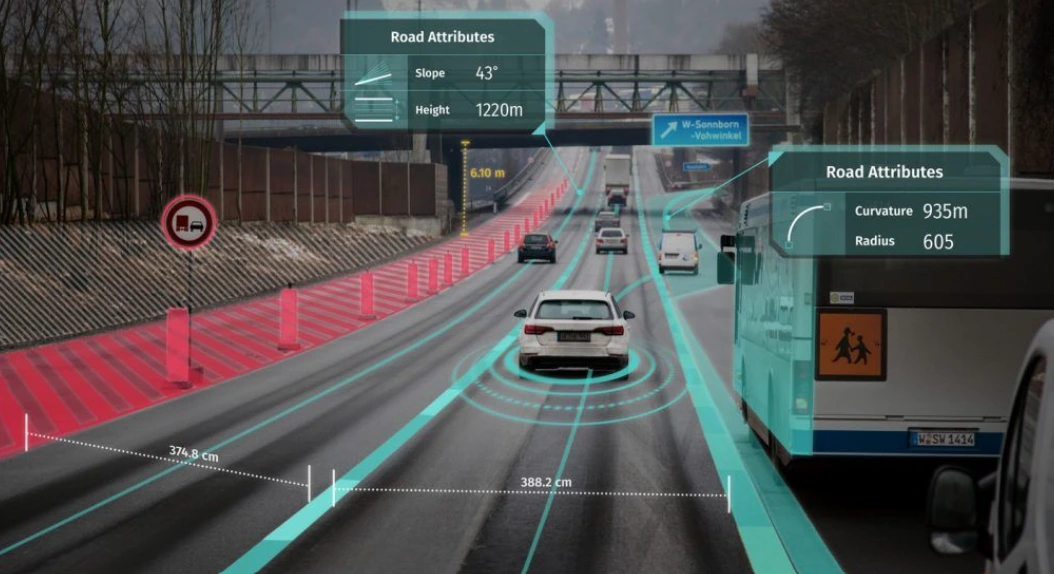

Telematics data collection encompasses a wide array of vehicle-related information, including vehicle location, speed, geographical data, incidents, fuel consumption, and various vehicle metrics. This comprehensive data provides fleet managers with a comprehensive overview of their entire fleet.

Most contemporary commercial vehicle manufacturers integrate telematics systems and GPS tracking devices within their vehicles. Alternatively, aftermarket GPS devices can be installed and powered by the vehicle's electrical system if necessary.

This technology facilitates inter-vehicle communication, fault tracking, penalty point calculations, and integration with business intelligence (BI) systems. Its versatile applications span across dash cameras, dispatching, route optimization, mobile forms, and remote diagnostics.

Insurers are keenly interested in analyzing the diverse driving habits of insured vehicles using telematics. These systems effectively identify factors contributing to poor driving practices and offer suggestions for improvement. Moreover, they contribute to Advanced Driver Assistance Systems (ADAS) alerts and foster vehicle-to-vehicle communication.

By monitoring driver behavior, telematics technology aids in cost reduction for maintenance, enhances safety measures and supports fleet managers in establishing regular maintenance schedules. Furthermore, it provides valuable insights into drivers' habits, enabling personalized coaching sessions and training programs.

Numerous automotive entities have begun investing in advanced telematics systems to gain a competitive edge. Combining application-specific telematics and computer imaging offers fleet managers extensive vehicle status information, reducing collisions and enhancing fuel efficiency.

The automotive sector widely embraces automated mobile vehicle inspection technology, amalgamating telematics and computer vision. This system allows drivers to upload images and gather data on vehicle health and potential issues, which is then analyzed and stored in a central database. Additionally, it seamlessly integrates with telematics devices, furnishing fleet managers with near real-time data.

Brief steps involved in Vehicle Inspection System

Creating a vehicle visual inspection system using computer vision involves several technical steps and algorithms. Here's a more technical breakdown of the process:

Data Collection and Preprocessing:

- Collect a diverse dataset of vehicle images or videos, encompassing various angles, lighting conditions, and vehicle types.

- Preprocess the dataset by resizing images, adjusting brightness, applying filters, and removing noise using techniques like histogram equalization, Gaussian blurring, or edge detection to enhance image quality and standardize the data.

Data Annotation:

- Label the dataset by annotating images with bounding boxes or segmentation masks indicating the location and extent of defects or components using tools like Labellerr.

Model Selection and Architecture:

- Choose appropriate computer vision models tailored for object detection, such as Faster R-CNN, YOLO (You Only Look Once), or SSD (Single Shot Multibox Detector). These models are adept at detecting and localizing objects within images.

- Select a pre-trained deep learning model (like VGG, ResNet, or MobileNet) as a base architecture and fine-tune it using transfer learning to adapt to specific vehicle inspection tasks.

Model Training:

- Implement the selected model architecture using deep learning libraries like TensorFlow or PyTorch.

- Train the model on the annotated dataset using stochastic gradient descent optimization techniques and loss functions like cross-entropy loss or mean squared error to minimize errors in defect detection and classification.

Augmentation Techniques:

- Employ data augmentation methods such as rotation, scaling, flipping, or adding noise to artificially expand the dataset and improve model generalization.

Validation and Testing:

- Split the dataset into training, validation, and test sets to evaluate model performance.

- Use metrics like precision, recall, F1-score, or Intersection over Union (IoU) to measure the model's accuracy and robustness in detecting defects.

Integration and Deployment:

- Integrate the trained model into a software system, considering hardware requirements like cameras, sensors, or processing units.

- Develop an interface allowing users to input images or videos for inspection and visualize the results.

Real-time Processing and Optimization:

- Optimize the model for real-time performance by leveraging techniques like model quantization, pruning, or using specialized hardware (e.g., GPUs or TPUs) for faster inference.

Monitoring and Continuous Improvement:

- Monitor the system in deployment, gather feedback, and collect additional data to retrain and fine-tune the model periodically.

- Implement iterative improvements by updating algorithms, incorporating new data, or refining preprocessing steps to enhance the system's accuracy and efficiency.

This technical process combines data handling, model selection, training, validation, deployment, and continuous improvement to develop a robust vehicle visual inspection system using computer vision. Each step involves intricate algorithms and techniques tailored to ensure accurate and efficient defect detection within vehicle images or videos.

Computer Vision and Telematics in Car Inspections

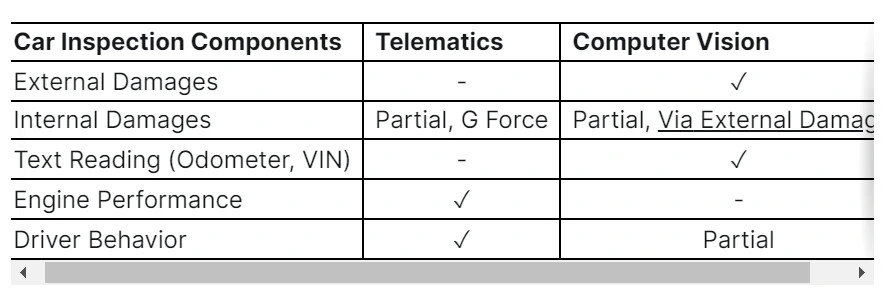

Telematics and computer vision technologies play complementary roles in assessing various components during car inspections. Each technology has its strengths, and when deployed together as part of a unified vehicle inspection system, they offer comprehensive coverage.

Let's delve into the key components of car inspection and how these technologies contribute:

Computer Vision for Car Inspection

External Damages

Computer vision excels in detecting external damages on a vehicle's body. Advanced computer vision methods can accurately locate and quantify these damages through photos and videos, streamlining the process for businesses and insurers when handling claims.

Internal Damages

Detecting internal damage involves both telematics and computer vision. Telematics provide crucial data such as g-force, acceleration, and driving behavior, aiding in assessing the impact's severity. Meanwhile, computer vision AI correlates external damages to likely internal damage areas, determining which components might have been affected.

Text Reading

Computer vision technology specializes in reading text from vehicle images or videos, automatically extracting information like VIN, odometer readings, and license plates. This text recognition helps prevent fraud by ensuring an accurate representation of the vehicle.

Telematics for Car Inspection

Engine Performance

Telematics gathers data related to engine load, temperature, and diagnostic information, analyzing various engine components like powertrain, sensors, and battery health, contributing to evaluating engine performance.

Driver Behavior

Telematics monitors and tracks driver behavior by logging distances traveled, fuel consumption, idle time, driving habits, and instances of harsh driving. This data aids fleet managers in understanding driver behaviors and implementing tailored coaching and training programs.

The integration of telematics and computer vision technology in a unified system ensures a comprehensive evaluation of a vehicle during the inspection, covering external and internal damages, text recognition, engine performance, and driver behavior, where each technology complements the other's capabilities.

What Are The Advantages Of Using Computer Vision And TelematicsTogether?

Combining telematics and computer vision presents several advantages, particularly in swiftly identifying issues related to panel alignment, fit, finish, scratches, dents, and scrapes within vehicles. The information gathered can seamlessly integrate into conventional business and dealership systems, generating comprehensive vehicle reports in a matter of seconds.

However, it's important to note that while these technologies excel in detecting various flaws, certain aspects like air conditioning and paint depth assessment may require separate systems that aren't yet part of the integrated solution.

Despite these exceptions, the amalgamation of telematics and computer vision offers numerous benefits over manual inspection methods. These technologies boast high accuracy in flagging defects without the need for manual verification. Leveraging machine learning models enables the detection of flaws, while the ability to personalize algorithms allows manufacturers to fine-tune these systems to suit their specific vehicles. This significantly accelerates the quality control process by identifying faults before they are perceptible to human inspectors.

The applications of these technologies extend across the automotive inspection industry, facilitating the verification of component assembly to ensure compliance with safety standards. Utilizing ultra-high-resolution imaging, these systems provide real-time insights into a vehicle's condition, capturing detailed images and videos that comprehensively showcase any damages or specification issues.

Primarily benefiting automotive insurance companies, these technologies have revolutionized claim estimation processes. By accurately determining and analyzing the most recent accidents and impacts, they assist in establishing the sides of the vehicle affected and the damaged parts, ensuring precise and consistent results during the claim estimation process. Car inspections can be facilitated through two modes: On-Board Diagnostics (OBDs) and smartphones.

Conclusion

The fusion of computer vision and telematics stands as a groundbreaking advancement in vehicle inspection. These technologies, when combined, offer a comprehensive solution for assessing vehicle health, covering external damages, engine performance, driver behavior, and more. Their integration streamlines the inspection process, enhances accuracy, and provides real-time insights into a vehicle's condition.

Despite some limitations in areas like air conditioning assessment, the amalgamation of computer vision and telematics presents numerous advantages. It swiftly identifies issues within vehicles, integrates seamlessly into existing systems, and accelerates the inspection process by detecting faults before they're visible to human inspectors. Overall, these innovations have revolutionized the automotive inspection industry, ensuring precise, efficient, and detailed assessments that benefit vehicle maintenance, safety, and operational cost-effectiveness.

Frequently Asked Questions

1. How does a vehicle inspection system work?

A vehicle inspection system employs a combination of sensors, cameras, and advanced technologies like computer vision and AI algorithms to gather data about a vehicle's condition. Through the collection of information about its exterior, interior, components, and structural integrity, the system analyzes this data to detect defects, damages, or deviations from standard specifications.

Using machine learning and AI, it identifies issues such as panel misalignment, scratches, dents, paint imperfections, or other anomalies. This information is then compiled into comprehensive reports or alerts, offering insights into the vehicle's state, which can be integrated into broader systems utilized by manufacturers, dealerships, or insurance companies for decision-making, quality control, or claims processing.

2. Why is vehicle detection important in intelligent transport systems?

Vehicle detection is crucial in intelligent transport systems (ITS) as it enables real-time monitoring and management of traffic flow, aiding in efficient traffic control, congestion management, and overall road safety. By accurately identifying vehicles on roads or in parking areas using technologies like sensors, cameras, or radar systems, ITS can gather essential data such as vehicle counts, speeds, and occupancy.

This data is pivotal for optimizing traffic signal timing, managing traffic flow, implementing adaptive traffic control strategies, enabling emergency response systems, and providing valuable insights for urban planning and infrastructure development, ultimately enhancing road safety, reducing congestion, and improving overall transportation efficiency.

3. How is computer vision used in the automotive industry?

Within the automotive industry, computer vision plays a pivotal role across diverse applications aimed at enhancing product quality. Appearance-related defects, particularly in painting, constitute a significant portion of customer returns for defective products. Typically, the identification of visual defects is carried out manually by operators.

However, the integration of computer vision technology has transformed this process, enabling automated and precise defect detection. This technology utilizes advanced algorithms and imaging systems to scrutinize vehicle surfaces for imperfections, significantly reducing reliance on manual inspections and ensuring higher accuracy in spotting defects related to appearance, thereby enhancing overall product quality and customer satisfaction.

Simplify Your Data Annotation Workflow With Proven Strategies

.png)